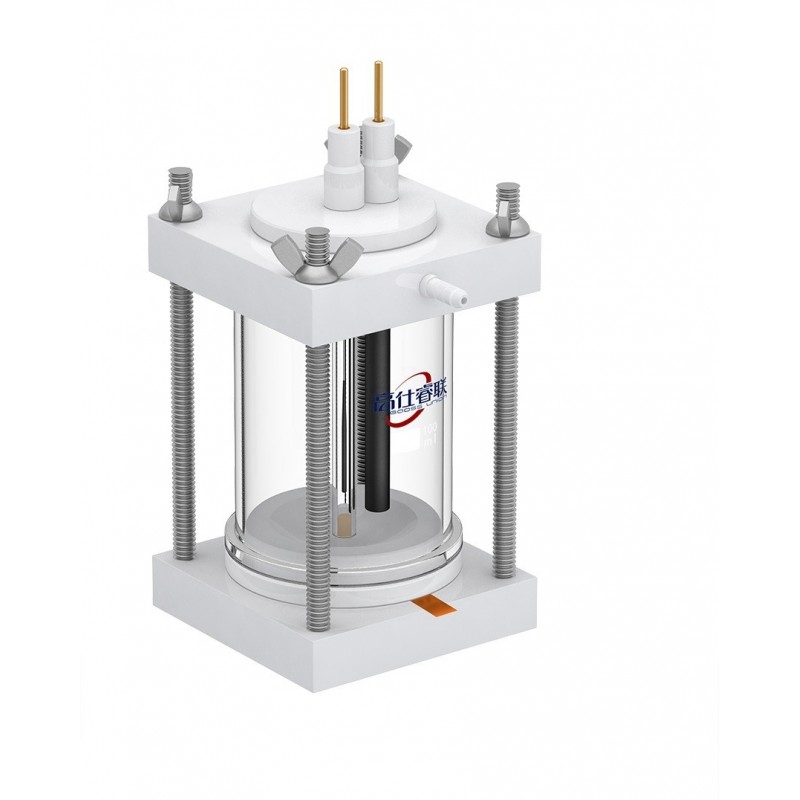

C011 coating evaluation test pool

1. The main body of the electrolytic cell is made of high borosilicate glass.

2. The working electrode sheet of the electrolytic cell is a sheet-shaped working electrode, and the sample installation is simple and convenient, easy to disassemble, and easy to handle.

3. The electrolytic cell can be used for the electrochemical experiment before the sample is scanned by the electron microscope, or for the corrosion test of the coating during the corrosion test.

4. The bottom of the electrolytic cell has a round hole with a fixed area of 1 square centimeter (the required size can be customized according to requirements), and an O0 ring that can be sealed. After placing the sample in the round hole, tighten the top four of the cell body by adjusting A screw to press the working sample tightly to achieve a sealing effect.

5. The conductive link of the working electrode of the electrolytic cell adopts the principle of bonding copper tape to the working sample to conduct the sample. The copper tape is convenient to use and easy to replace after corrosion, which can better ensure the conductivity.

6. The electrolytic cell is divided into two forms: single-layer and double-layer. The double-layer adds a constant temperature water bath function on the basis of the single layer. The circulating constant temperature water is continuously passed into the jacket layer of the electrolytic cell to make the inside of the electrolytic cell Achieve a constant temperature effect.

7. Electrolytic cell cover material: PTFE, the size of the cover varies according to the volume of the electrolytic cell.

8. Copper tape: need to be purchased separately

9. Auxiliary electrode: graphite electrode (need to be purchased separately)

10. Reference electrode: silver silver chloride electrode (need to be purchased separately)