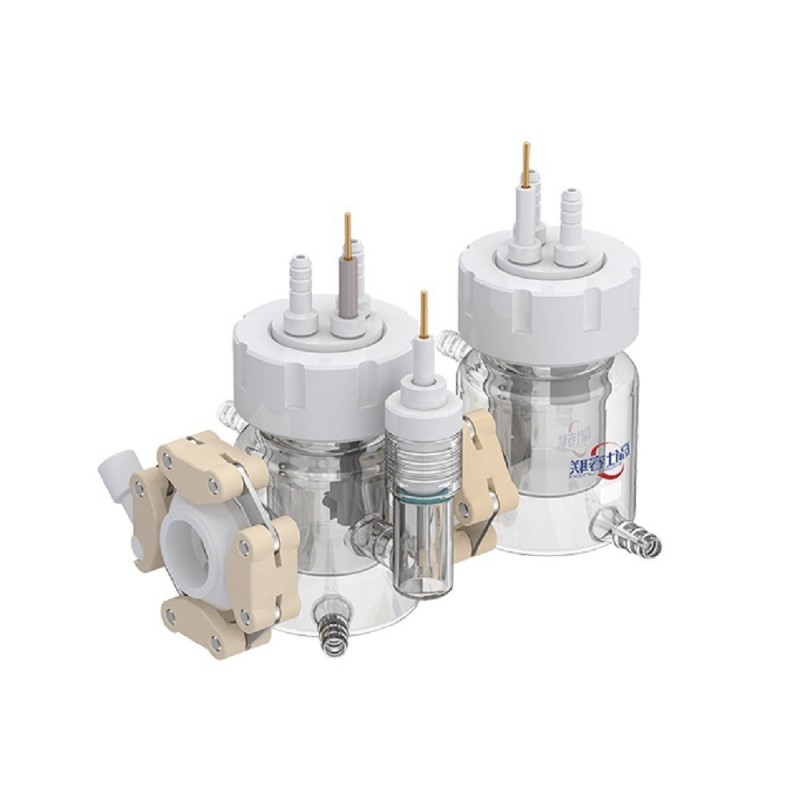

C025 replaceable membrane 3H electrolytic cell

1. The electrolytic cell is upgraded on the basis of C008 -2, adding-

2. The light window of the electrolytic cell is made of quartz, and the light transmittance is greater than 95%

3. The light window part of the electrolytic cell is connected with the cell body by a lock ring to ensure sealing and facilitate the replacement of the quartz light window.

4. The electrolytic cell realizes atmosphere protection by adding valves and aeration equipment, and the valve connected to the aeration device is the direction of air intake

5. The electrolytic cell is an absolutely sealed system and can be evacuated through the valve [] (less than -1Mpa). The electrolytic cell can be slightly pressurized, and the pressure should not be greater than 0.5MPa for safety reasons.

Due to technological limitations, the inner glass of the double-layer electrolytic cell is relatively weak, so pressurization is prohibited. 6. The working electrode, auxiliary electrode, and reference electrode of the electrolytic cell must be customized to match the electrolytic cell.

7. The reference electrode of the electrolytic cell is divided into the working electrode and connected by the Lukin capillary, which effectively reduces the R drop.

B. The aperture of the tip part of the electrolytic cell Lukin capillary projecting into the working electrode chamber cannot be greater than 0.2mm.

9. Agar can be added to the Lukin capillary of the electrolytic cell to reduce the flow rate of the electrolyte.

10. The reference electrode chamber of the electrolytic cell is sealed with internal threads, which must be sealed when in use to effectively avoid liquid seepage between the reference electrode chamber and the working electrode chamber due to the connector effect.

11. The cell body material of the electrolytic cell is high borosilicate glass

12. This electrolytic cell is often used in a three-electrode system. The volume of the electrolytic cell ranges from 30ml to 500ml, and it can also be customized according to requirements.

13. The electrolytic cell is an absolutely sealed electrolytic cell system. The cathode chamber (working electrode) and the anode chamber (contrast electrode) are separated by ion membrane (provided by the user), and the two chambers are sealed and linked by a chain to facilitate the replacement of the diaphragm.

14. The glass sealing part of the working electrode chamber and the contrast electrode chamber of the electrolytic cell adopts an external threaded port design, and the inner core adopts a 360-degree rotating PTFE, so that the electrode accurately corresponds to the channel (the general electrode is parallel to the membrane). Tighten the outer cover made of POM material for sealing.

15. The electrolytic cell is equipped with an aeration device that can ventilate below the liquid surface, and aeration devices of different shapes are selected for the atmosphere according to different experiments. For example, straight aeration is used for carbon reduction, and L-type aeration is used for nitrogen reduction.

16. The electrolytic cell can add a sampling port on the cell body, and an additional cost is required at this time. 17. The 10ml electrolytic cell is designed with internal thread, please refer to "C025-10" for details, but no valve can be added

18. The electrolytic cell is divided into two forms: single-layer and double-layer. The double-layer adds a constant temperature water bath function on the basis of the single layer. The circulating constant temperature water is continuously introduced into the jacket layer of the electrolytic cell to make the inside of the electrolytic cell Measure the melting wave to achieve a constant temperature effect